Family steps into the future with RoGator WEED-IT

26 July 2022

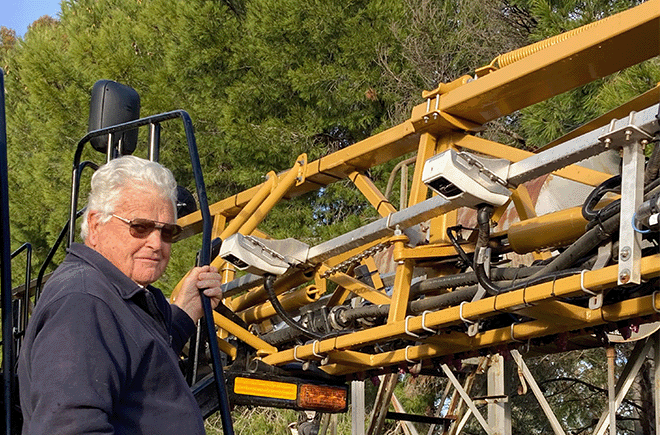

May we all be as productive and willing to learn in our 90s as Peter Whykes.

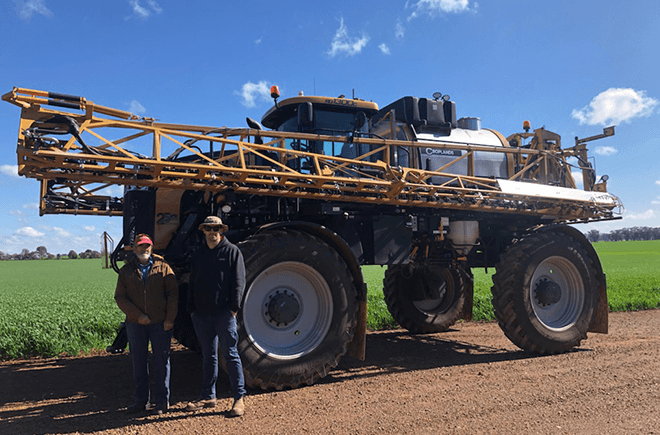

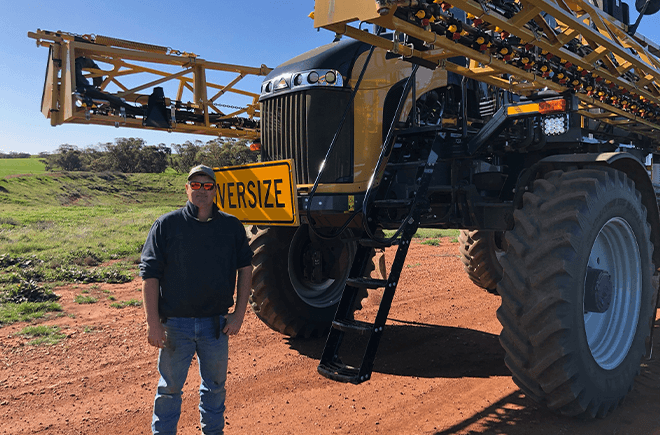

Now 91, Peter and his son Chris are the primary sprayer operators on the family’s cropping farm, and they are mastering a new RoGator 1300C with WEED-IT spot spray technology.

Three generations of the Whykes family work their 4700-ha dryland farm west of Charlton in Victoria’s Mallee region. They produce barley, wheat, canola, lentils, peas, fava beans, lupin and vetch and oaten hay.

Because they sow their crops using direct drill or minimum tillage, they depend on agrichemicals to control weeds. They use their sprayer to apply a full range of crop protection – herbicides, insecticides and fungicides.

In April the family took ownership of their second self-propelled RoGator, which is equipped with dual spraying technology. It can do traditional blanket spraying or use its WEED-IT Quadro sensors to target individual weeds.

Peter says he and his sons were impressed with their previous 6000-litre RoGator 1300B self-propelled, so they were keen to upgrade it for the new 7000-litre RoGator 1300C.

“We bought the first RoGator in this area. It is a great machine with a strong boom. We ordered the new one with WEED-IT sensors because we want to reduce our chemical usage.

There are two big benefits to using less chemicals. One is that it is better for the environment and our soils, and the second is we will save money and time.

Peter Whykes

The Whykes family was hoping the new sprayer would arrive as scheduled at the beginning of the year because they plan to use its spot spraying capability during late summer and early autumn.

As it turned out, it did not arrive until April. Although it was late, it did arrive in time for them to see how effective it is. Both Peter and his son Jon are impressed.

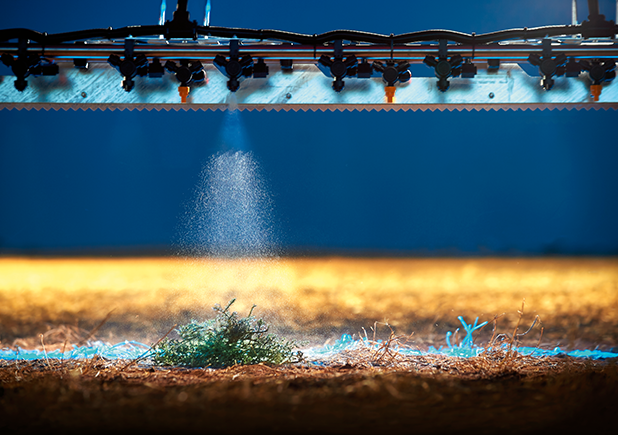

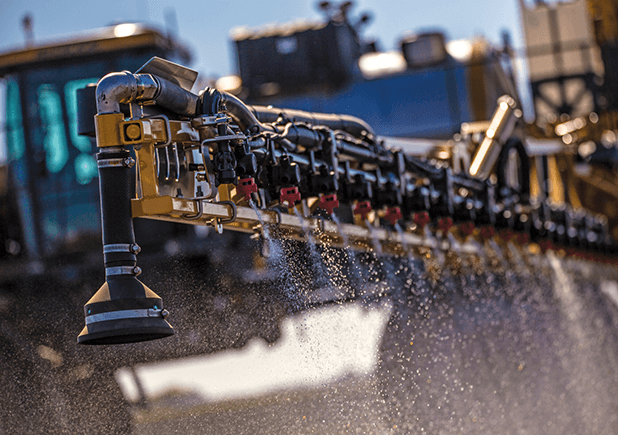

“The sensors need to be able to distinguish the green weeds against brown soil, so we will mainly use spot spraying to apply glyphosate and paraquat during the summer fallow prior to sowing.

“It seems to be very accurate and it has done a good job. We were able to target weeds with the sensors while operating at 17-18 kph,” Peter says.

Jon estimates the WEED-IT spot spraying technology will reduce their chemical use during summer and autumn by 50-80 percent.

We would have saved $100,000 if we had used the WEED-IT over the whole summer. We did one job for a neighbour on contract and we used 30 percent of the amount of chemical we anticipated to do the job.

John Whykes

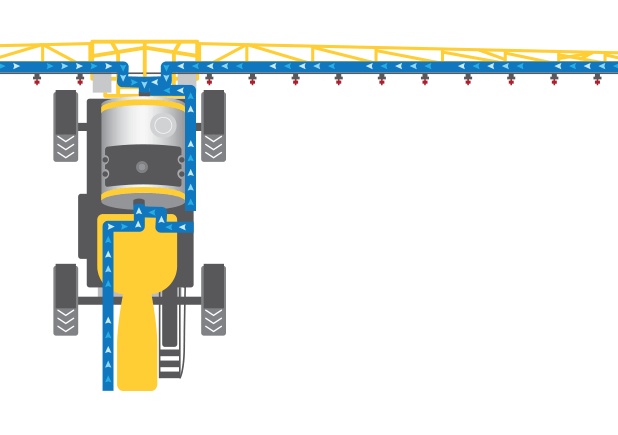

During blanket spraying, Peter says it is easy to prime the boom. An agitator in the tank works continuously and the product is continuously pumped through the boom so there is not a delay when spraying starts.

EASY TO CALIBRATE

The RoGator 1300C is also very easy to calibrate and has impressive section control, both of which come down to Capstan Pulse Width Modulation (PWM) technology. PWM regulates the application rate independent of pressure and it gives the ability to control every nozzle individually.

With Capstan PWM, 50hz solenoids mean nozzles constantly switch on and off up to 50 times per second. This gives the ability to vary the amount of time a nozzle cycles, making it possible to vary application rates while keeping the pressure constant.

“Using the previous system, if you wanted to increase the spray rate, the pump sped up and that increased the pressure so a bigger volume of chemical went out. The problem with that is it can encourage spray drift through fine droplets as the pressure increased,” Jon says.

“With this system, you put in the preselected application rate and pressure. As the speed of the sprayer varies, the pulsing rate of the nozzles adjusts to maintain the rate and the pressure. You know that 99 percent of the droplets are the right size to hit the target.”

nozzle control

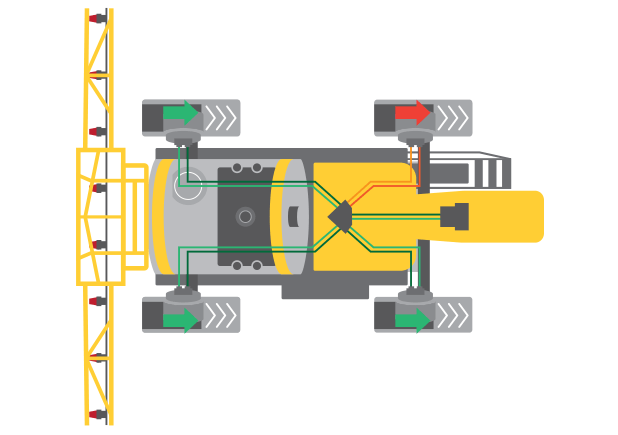

Jon says this system also gives full individual nozzle control. This includes turn compensation so that during turns, each nozzle applies the exact rate required to make coverage consistent across the boom.

Individual nozzles also turn off if they are approaching an area that has already been sprayed. Section control in the Whykes’ previous RoGator deactivated and activated a cluster of nozzles.

This meant a number of nozzles would turn on together, even if only one in the cluster was over an area that had been not been sprayed. This could lead to over spraying and the extra costs and potential crop damage it can cause.

Boom auto fold and cruise control

“Another big step up with our new RoGator is the auto fold function for the boom,” Jon says. “With this one, there is just a single button that you push to fold out or in.”

“The new RoGator also has two auto cruise controls. You select the work speed and the turning speed and then you can just switch between them.”

sustainable spraying with WEED-IT

With its ability to reduce drift and spot spray, the new RoGator with WEED-IT is helping the Whykes family keep up with the very latest in technology and stay ahead of the regulators.

They believe that in the future all farmers and contractors will have to be able to show that they are only using the chemicals they need to use, and that they are only applying them where they need to go.