WEED-IT AUTONOMOUS SOLUTIONS

7 JANUARY 2025

Two Australian Companies Partner to Bring an Autonomous Optical Spot Spraying Solution to the Australian Broadacre Market

Croplands, Nufarm’s emerging solutions spray equipment platform, has partnered with SwarmFarm, a specialist in autonomous robots to launch a fully integrated optical spot spraying solution for the Australian broadacre market.

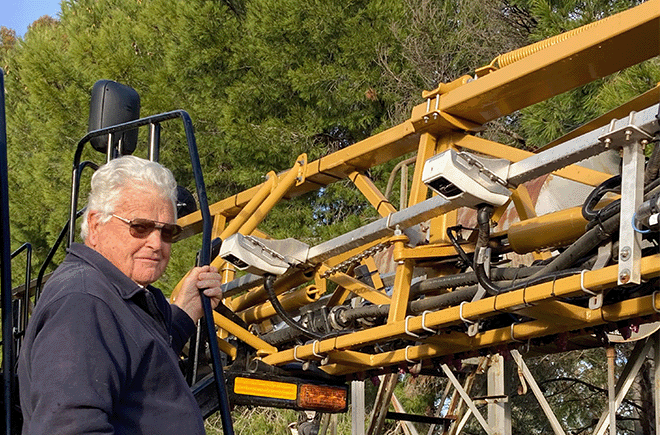

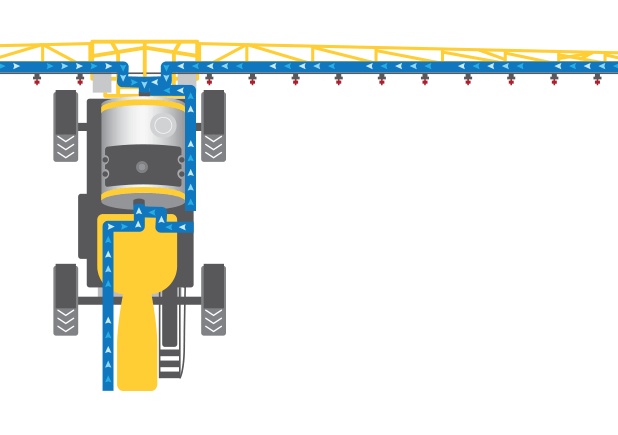

Croplands has a strong pedigree in engineering quality, large scale broadacre spraying solutions suited to the harsh Australian environment. The Pinto trailed sprayer range represents Croplands design philosophy: robust design and generous dimensions resulting in unmatched durability, simplicity and functionality. Croplands has engineered a Robot Ready Pinto with suspended gooseneck attachment, 3000L Tank & 18m or 24m booms which seamlessly integrates with Swarm Farm’s autonomous SwarmBot. The SwarmBot is an articulated autonomous tool carrier on 3m centres ideally suited to broadacre applications.

Lachlan Coom, WEED-IT Product Lead, Croplands, says “We have been testing our Robot Ready Pinto in numerous soil types and terrains across Queensland, including the heavy black soils on the Darling Downs.”

Apart from the excellent maneuverability of the gooseneck design, we were also impressed by the boom’s stability with the auto height control exceeding expectations.

Lachlan Coom, WEED-IT Product Lead, Croplands

“We were also very happy that the integration went smoothly between the sprayer and robot when setting it up for it’s initial test run. SwarmFarm really know their stuff.” Says Lachlan.

The Robot Ready Pinto 3000 boasts a 24m or 18m fully hydraulic steel boom, 3m axle with rubber block suspension, the newly designed gooseneck attachment is also fitted with a unique suspension system. An additional poly mounted tank is fitted to the gooseneck of the chassis can be used as a high-capacity flush tank or alternatively as extra spraying capacity for large jobs.

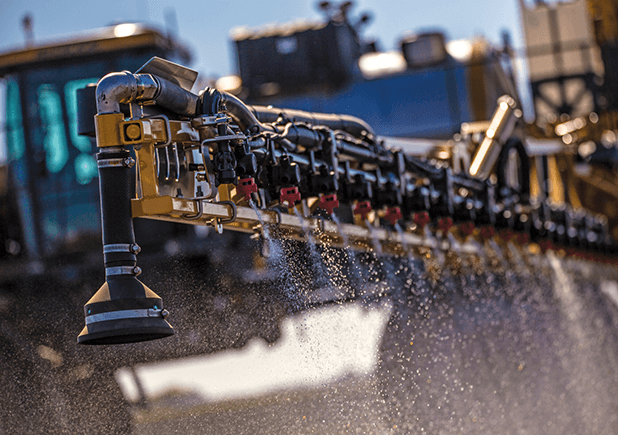

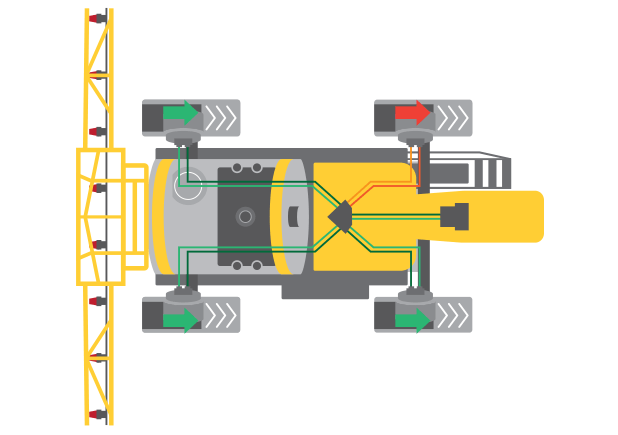

“Croplands specifically designed the boom on the Robot Ready Pinto to enable twin line plumbing and sensors, which are pointing directly to the ground.” Says Lachlan. The newly designed boom delivers a high specification liquid system accurately and compliments the robust chassis. The chassis features 1-inch stainless steel boom plumbing, triple nozzle bodies and standard boom recirculation being supplied by a stainless-steel high-performance Ace centrifugal pump. Dual flow meters are fitted as standard equipment to allow for highly accurate PWM blanket spraying as an addition to the standard spot spraying the WEED-IT Quadro system is renowned for. Left and Right fence row nozzles, a standard high clearance of 1000mm for in-crop capabilities and easy-to-use fill panel with 2-inch fill, tank rinse, agitation & a handwash tank round out an exceptional package that ticks all the boxes.

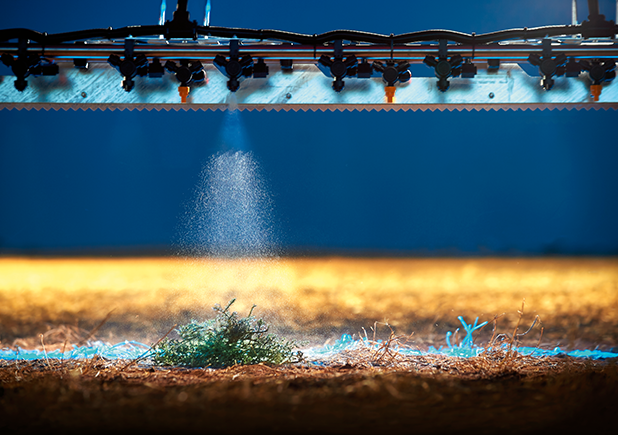

Standard inclusions make spraying simple with work lights fitted, along with additional blue lights for nighttime spraying.

Braydon Bullock, grower located at Oakey in Queensland saw the Robot Ready Pinto integrated with the SwarmBot on his property during Croplands and SwarmFarm’s testing. “The unit looks solid. I like how the WEED-IT sensors are mounted at a right angle to the boom facing straight down into the stubble, I note there is also plenty of room for the boom plumbing to be mounted.” Braydon says.