Performance, stability, comfort

04 August 2020

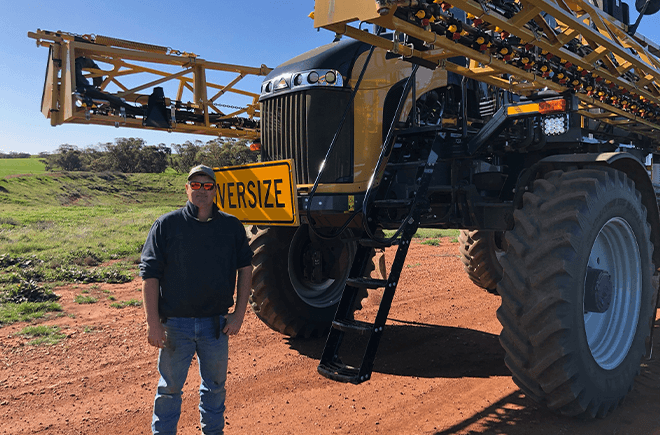

Todd and Brooke Orrock bought their first RoGator self-propelled sprayer after an accident that involved an insurance company and the need for a quick changeover.

There was a RoGator on a dealer’s lot, 40 km away and Todd was always keen on the brand, so the deal was done.

When the family bought their second RoGator, it was no accident. In February they bought a RoGator 1300C for their 2400-ha cropping farm near Murray Town, South Australia.

It is a family farm owned by Todd, his mum, Karen, and his wife, Brooke. Todd and Brooke’s children, Sophie and Mitchell, also work in the business.

They grow wheat, barley, canola, beans, export hay and some lentils. The last three years have been tough with drought and late season frost, but even so they have managed to get crops. This season is looking better.

Todd says the things he liked about the first RoGator are still there, but the new model had enough new technology that it was worth updating.

The Orrocks specified their RoGator 1300C with a 36m steel boom. Todd says he would have liked to go wider, but 36m fits with their tramlines, where the urea spreader is the limiting factor.

Along with looking after the family farm, Todd sprays for neighbouring farmers on contract. The contracting gives him an income, and it means he has newer gear for his own farm.

“We specialise in desiccation and fungicides in canola and beans.”

He can do that because he invested in crop dividers and sprays tall crops without damage.

There are many things he likes about RoGators.

I like the simplicity of the drive system and the stability of the booms. RoGators carry the boom really close to the axle, so they don’t get a waggle up.

Todd Orrock, Murray Town SA

Stability also matters for accuracy. The Orrocks farm is undulating country, and keeping the nozzles at the right height mitigates the risk of drift.

Stability also minimises stress on the machine and the operator. The boom wings go back and reset during cornering, controlled by a ram that works as a big shock absorber.

Todd has to work in small paddocks, and the ability to spray folded up at 60 ft is another advantage.

The boom is divided into 35 sections. Every four nozzles have their own section. The nozzles are 250 mm apart.

It has the ability to apply variable rates as prescribed by a map, but Todd does not use this feature.

Then there is the continuous boom recirculation.

I am in love with it and it should be standard on every boom sprayer, especially for contractors changing brews every day.

Todd Orrock

He used to either park in a corner and prime up the boom, or else he did laps.

“It took 300 litres of product to ensure it was primed. Now I can prime on my way to the paddock and start as soon as I am in the gate. It cuts down the boom sprayer’s hours.”

Another advantage of boom recirculation is that left-over product goes back into the tank. It keeps the boom clean with water, which minimises contamination and makes decontamination easy.

Todd describes the RoGator’s suspension as like driving a big bean bag.

“It has air suspension on the cab and boom. I have had major back surgery with discs removed. At the end of a day spraying, I get out and I am still walking. I couldn’t do that with our old trailed sprayer. Comfort is good.”

He usually drives at 25 kph and says it is smoother than going slower.

The RoGator 1300C has a 6300-litre tank. It does make for a heavy load, but Todd says for a self-propelled it is not overly weighty. He can carry less product if traction is an issue.

Its tank has automatic agitation. Agitation reduces as it empties to limit foaming.

The RoGator has a 60 kph road speed, which appeals to the contracting side of the business. Unfolding from transport mode is done with the push of one button.

Todd does not want to cart a trailer, so he uses the RoGator as its own batching plant and gets water where he is working.

He says his RoGator 1300C is more fuel-efficient than his previous one. Traction is also better with power to all four wheels.

“It has a smarter drive that doesn’t have to run at full revs all day. It matches the engine speed to the load.”

“We had a wet block this year and the old one would have spun a hole. This one moved the drive between wheels and drove through it.”

RoGators come with their own screen and controller, but they can also play nicely with others. Todd runs tests for a company that supplies GPS and control units, and he wanted their software in his sprayer.

Croplands worked with him and his GPS company to ensure it happened.

Easy operation is another benefit of the RoGator. Todd often sprays at night when the temperature has dropped, so this is a huge advantage.

“Maintenance is also easy. There are only two filters on the spraying side, so cleaning out is a breeze.”

Todd bought his RoGator 1300C directly from Croplands. He says they are good to deal with and he is lucky to have an agent just 40 km away.

It is working very well. Product recovery and boom recirculation are amazing features.

Todd Orrock