RoGator makes spraying a breeze

19 February 2020

THERE are some things about having so-called ‘fruits’ or new technology, that just makes work a bit easier.

And if you’re spraying, the bonus is maximising windows of opportunity to achieve high weed kill rates.

For Chapman Valley farmer Ian Grant, who replaced his Croplands RoGator 5000 litre tank capacity 1386B model with a new 6000L tank capacity1300C model, comparing performance between the two models is almost chalk and cheese.

And that’s despite the 1386B living up to expectations with high productivity and weed kill efficiency.

It’s the ‘fruit’ that makes the 1300C a dream to operate.

Take its trade-marked SmartDrive system, which links the tractor management system and drive functions, so no operator input is needed.

The tractor management system controls engine RPM and hydrostatic drives, and operators who have tractor management systems, know how efficient they are at providing the greatest torque curves at the lowest RPM.

Croplands says SmartDrive adds to this with even better fuel economy because the operator can match RPM to operating speed. In fact Croplands claim the 1300C provides 24 per cent more fuel saving than its B Series predecessor with an operating consumption of about 15 litres an hour.

For Ian, who highly rates the SmartDrive system, he averages 11L/hr and has further enhanced fill times with a front-fill system to bypass all pumps which allows him a five minute fill-time from his nurse tank.

SmartDrive also features two-speed cruise control – one for ‘in-paddock’ and the other for ‘end-row turn’- from its all-wheel traction control with a single-hydrostatic, four-wheel drive system. Shuttle shift makes changing direction fast and easy.

Croplands believe this is an industry first that provides power to the wheels with no slip.

If the system senses a wheel slipping, it diverts power to the wheels that still have grip to keep the sprayer moving.

In undulating and boggy conditions, it’s a handy feature and Mr Grant also likes the

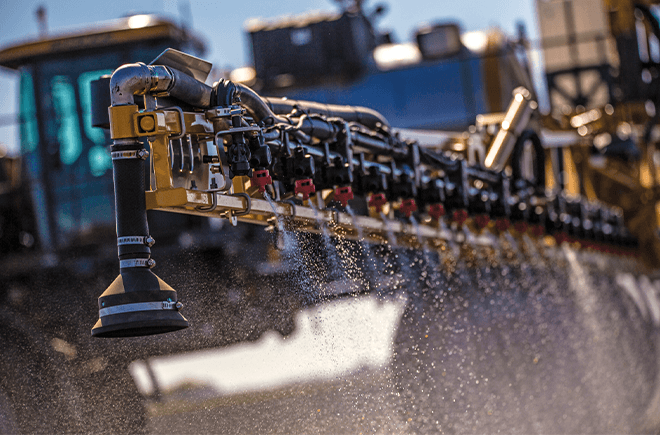

Another big feature is a fully pressurised circulating boom with three circuits, providing even pressure across the boom to within plus or minus 1psi.

Called FlowLogic, this re-circulation plumbing keeps product moving through the boom, plumbing and filters to reduce chemical build-up and help eliminate blocked nozzles.

The boom is certainly easier to clean. There’s no sediment build-up and all the chemical gets recovered back to the tank.

Ian Grant, Chapman Valley WA

An optional Capstan PinPoint system uses blended pulse width modulation technology to achieve complete individual nozzle control.

In conjunction with the self-priming boom, it means instantaneous and constant spray pattern to eliminate over and under-spraying.

“It’s an excellent feature because I’ve got irregular-shaped paddocks so it eliminates a lot of overlap and scorch,” Mr Grant said.

“It’s also worth mentioning that with this new spray system we can comfortably spray 120 litres a hectare of water rates up to 30km/h.”

Mr Grant also likes the auto-height boom control which he says is a “huge plus” in undulating country and “the reaction time is good”.

Then there’s the LiquidLogic system, which helps operators simplify their jobs, reduce potential for off-target application, make clean-out faster, easier and more thorough and reduce product waste.

“It used to be a huge issue decontaminating with SU residues before spraying canola and we’re also using Intervix from brome and wild oats in wheat and that can be flushed out before using the RR canola sprays,” Mr Grant said.

Other key features of the LiquidLogic system include a “hold at minimum” pressure setting across the boom that helps ensure a consistent spray pattern to keep product on target at low speed and the ability to maintain a +/- one psi variation across the boom.

Section control for either 35 sections with 25cm (10in) or 37.5cm (15in) spacings or 36 sections with 50cm (20in) spacings, are standard with the AgControl rate controller.

Finally, variable displacement control of the product pump manages and limits speed to 5000 rpm to help prevent pump failure.

ClearFlow recovery is how Croplands describes the industry’s first full-recovery system. Air is used to force product from the boom back into the tank, leaving less than 10 litres in the system while a self-priming boom enables product flow through the entire boom once the product pump and recirculation are turned on.

In addition Mr Grant also opted for a WEED-IT spot spraying system which entails fitting cameras on the boom with appropriate wiring harnesses.

“It’s a bit of a hassle but it converts the RoGator into a spot-sprayer,” Mr Grant said.

According to WEED-IT it has the best sensors on the market to recognise chlorophyll making it just as effective in the dark.

“I reckon I’ll get my investment back in two years with the chemical I’ll save,” Mr Grant said.

I’m estimating I’ll save between 80 and 90 per cent on chemicals.

Ian Grant

In the cab of the 1300C, a 26 centimetre touch-screen AccuTerminal allows intuitive, easy-to-learn control and monitoring of machine functions, such as the new cruise control and shuttle shift speed along with drive sensitivities, headland control and tractor management system (TMS).

The AccuTerminal can be used to access functions within the re-designed AgControl rate and section control system as well as spray functions such as pressures, auto agitation, boom clean-out, product rinse and recovery.

Automatic guidance and AGCO’s full suite of Fuse precision application, documentation and machine tracking tools are all controlled through this single operating terminal.

Dual-band cellular plus world-wide satellite connections, allow machine tracking and performance through Fuse Connected Services via AgCommand.

Originally published in Farm Weekly as “RoGator ‘fruit’ makes spraying a breeze”, Ken Wilson.